I plan to experiment with cutting dry.Ī good place to get answers for PCBGcode is this Yahoo Group I use a Dewalt DW660 at 30k rpm with a PreciseBit EM3E8 isolation bit. I'm still playing with the etching feedrate, I think I can go higher. Depth for drilling holes is right below that. The depth for the text is also set on the first tab.ĭepth for cutting the copper traces (etching) is on the Machine tab in the Z-axis section called z-down. If you have text on layer 46, then that gcode is put into a text gcode file. What I like to do is make my line width in Eagle the same width as my milling end mill and adjust the line position so the edge is where I want. So if you have a 2" x 2" PCB and just have a thin outline line on layer 46 and a 1/8" end mill, your board will be 1-7/8 x 1/78. Note, when you mill the board outline, pcb-gode just goes down the centerline of the line on layer 46. Pcbgcode will generate gcode for the milling based on whatever you have on layer 46 in eagle. I like to go a little deeper, but you can go shallower if you don't want to cut into whatever kind of board you have under the PCB. So the depth is about the same same as the thickness of the PCB. On the first tab, milling refers to cutting out the PCB board's perimeter, not the cutting of the copper traces.

#Grbl controller candle 1.17 vs pdf

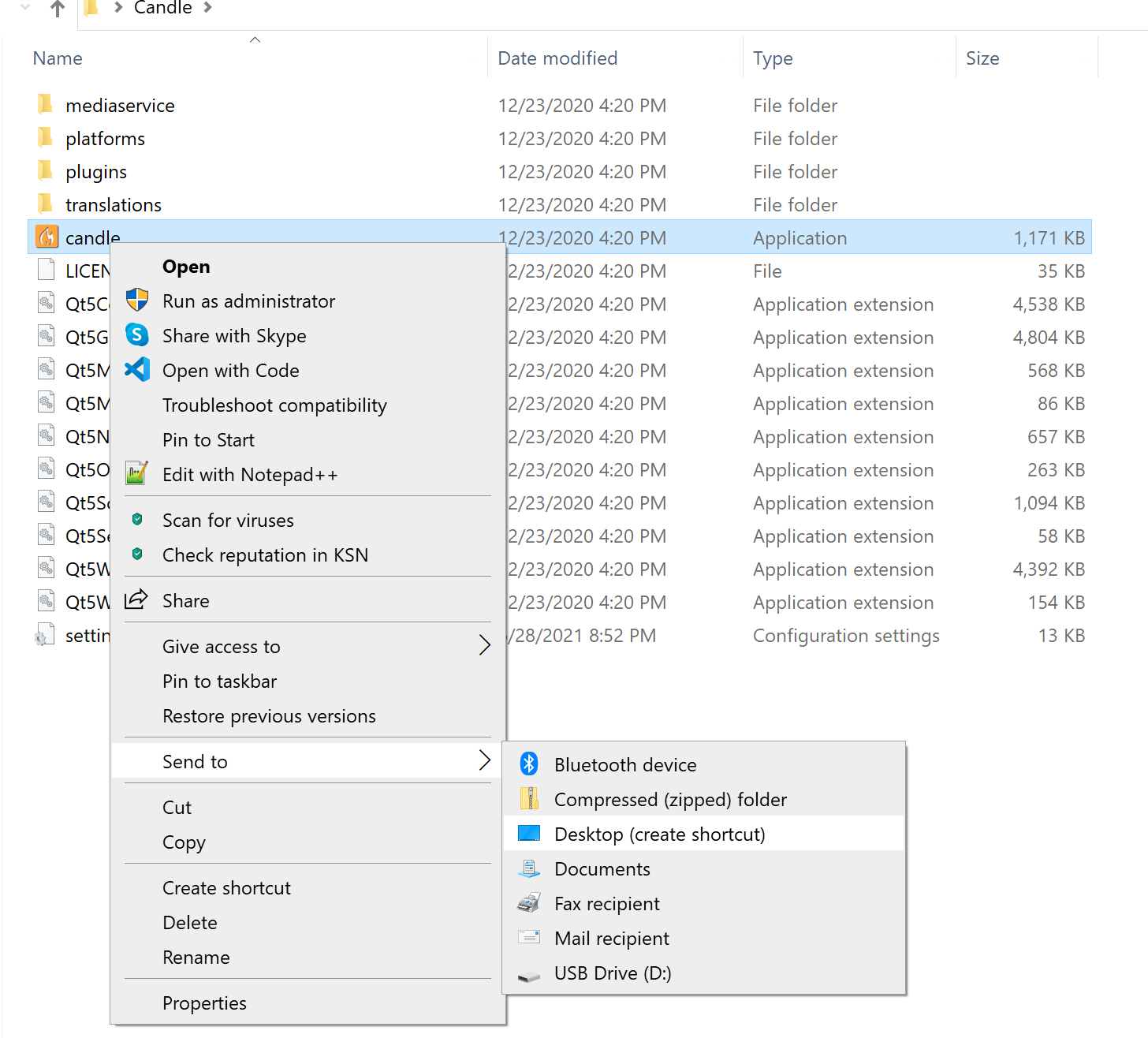

I just don't seem to understand what the difference between those two are and it doesn't seem clear in the PDF Example - G0 G54 G17 G21 G90 G94 M0 M5 M9 T0 S0.0 F500.0 Shows the GRBL version and source code. Displays the active gCode modes in the GRBL parser. But then I go over to the machine tab where it shows the actual end mill and explains what the different parameters are. Reset GRBL Kill Alarm Lock Run Homing Cycle Lists work coordinate offsets (G54-G59), Predefined positions (G28 & G30), Coordinate offset (G92), Tool Length Offset (TLO) & Probing cycle (PRB). For example, on the first tab in the board section, I select generate milling and set the depth. Has anyone else used the probing script from the above link using GRBL? Is there anything better that people have used using the stock motor controller?Īiden1015 wrote:I saw the manual, but it didn't seem to help. I ended up with the same problem as to be expected one side went through all the copper, then as it moved across the x-axis it got thinner and finally non-existent.

So I decided to say screw it and hoped my pocket did a good job leveling it to my didn't. orial.htmlįirst problem I ran into was that when I tried to run it, it didn't move the steppers at all even though everything was plugged in and I was on the right COM port.

But out of paranoia I looked for autoleveling scripts using the v-bit as a probe from here. Half is etched through, and then it gets lighter and then misses the copper clad all together.įirst thing I did was use some plywood and made a 1mm deep 4"圆" pocket to tape down my copper clad using the thin double-sided tape. I use Eagle and the PCB G-Code ULP but ran into the typical problems with a unleveled bed. I've had my Shapeoko 2 for a few weeks now working my way up to circuit boards.

0 kommentar(er)

0 kommentar(er)